|

|||||

|

Cross Section Type – Beam Theory

| |

|

Concrete cross section

|

Timoshenko’s theory. Based on first order shear deformation theory, cross sections remain plane and undistorted after deformation.

|

|

Steel cross section

|

Bernoulli-Euler theory. Shear deformations are neglected, and plane sections remain plane and normal to the longitudinal axis

|

Create a concrete cross section

The dimensions for different concrete shapes are shown below:

a: height.

b: width.

c: outer diameter.

d: web thickness.

e: top flange length.

f: top flange thickness.

g: bottom flange length.

h: bottom flange thickness.

i: thickness of vertical web.

j: thickness of vertical web.

k: wall thickness.

This is the whole group of concrete sections available to perform a beam structural element. For further information about the captured concrete section and the concrete section defined by points, click on Generic concrete sections.

Once the properties required for the concrete section are applied, the section is entirely defined. The property bar gives the following information:

Solving a model taking into account the mechanical properties of a section instead of the tessellation, is equivalent to solving the model with a generic section.

In regards to the mechanical properties type, four types are available: gross, net, homogenized and defined by user.

REINFORCEMENTS

CivilFEM allows the definition of reinforcement for a concrete beam section, once required section has been defined.

Both a concrete material and a reinforcement material are necessary to define a reinforced concrete section. This reinforcement material will be used to reinforce the whole section, both longitudinally and transversally.

In the picture below all available reinforcement types are shown.

Reinforcement for beams can be defined for: bending + axial, shear and torsion loads. The mechanical cover (mc) is defined by the user, and will affect the rebar location.

Bending + Axial reinforcement

The reinforcement class defines if reinforcement is fixed or scalable. The user may design a beam with an insufficient reinforcement amount. CivilFEM will provide the needed reinforcement for those reinforcements in which the "Scalable" option is activated after performing a design by code. On the other hand, if "Fixed" option is activated, will not be modified. This tool will be very useful for "Design beam" tool.

Point 1 and Point 2 make reference to both ends of the same reinforcement line.

Geometry properties bar option defines if reinforcement must be set as a straight segment or as a circumference.

The bottom part of this chart will be detailed below:

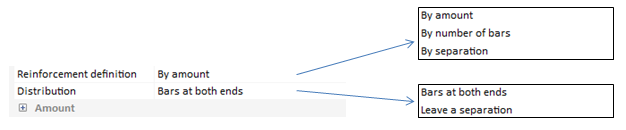

The reinforcement definition may be done by amount, number of bars or by separation.

By amount By number of bars By separation

Distribution defines the reinforcement location inside the section (formulation and pictures in "Reinforcement" chapter.

CivilFEM provides the proper number of reinforcement amount depending on the section type the user wants to create. However, if another reinforcement group needs to be added, it can be easily done within the "Add" option inside the contextual menu.

The user can make use of the "Show" option to visualize the reinforcement status.

Shear reinforcement

Only one group of shear reinforcements may be defined for each cross section.

Angle with respect the longitudinal axis (90º by default):

Torsion reinforcement

Only one group of torsion reinforcements may be defined for each section. Torsion reinforcement has two components:

|